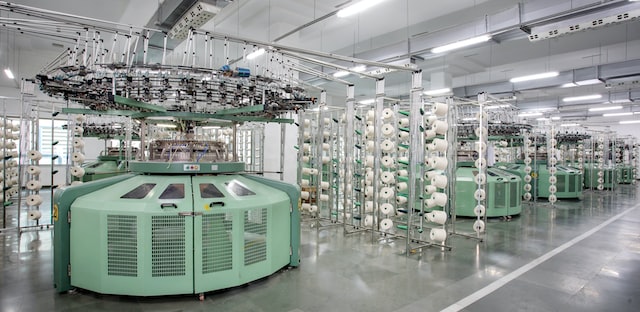

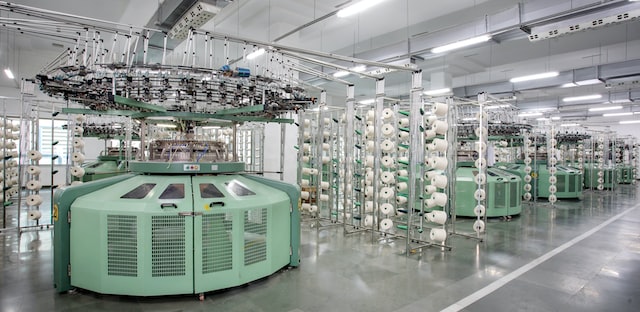

The manufacturing sector is one of those industries that affect almost everyone. This industry is undergoing a radical shift in its operations thanks to the advancement of technologies like artificial intelligence (AI), Internet of Things (IoT), and more. These technologies have changed how several operations in this industry are executed.

These data-driven technologies that are being adopted in the manufacturing industry have been very critical for the fourth industrial revolution (4IR) or industry 4.0. This revolution in the manufacturing industry is mainly characterized by data-driven decisions that have significantly improved the effectiveness of operations.

In today’s article, we will discuss how AI, one of the core technologies in the 4IR, is impacting manufacturing. We shall share some of the common use cases of AI in manufacturing and its benefits to the various stakeholders in the industry.

What is AI in manufacturing?

AI in manufacturing refers to the integration of computing and AI capabilities to automate several manufacturing functions that were initially done by humans. As we shared with you earlier, AI is one of the core technologies of the 4IR. The use of AI in this industry has escalated in the last two decades, thanks to the advancements in computing.

A 2020 study by McKinsey and Company shows that 4IR technologies could create up to $3.7 Trillion in value by 2025. AI alone is expected to contribute between $1.2 to $2 Trillion in manufacturing and supply chain management by that time. These numbers clearly show the potential of AI in this industry.

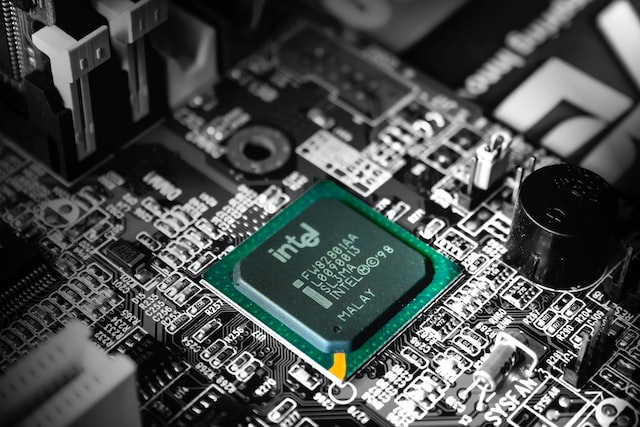

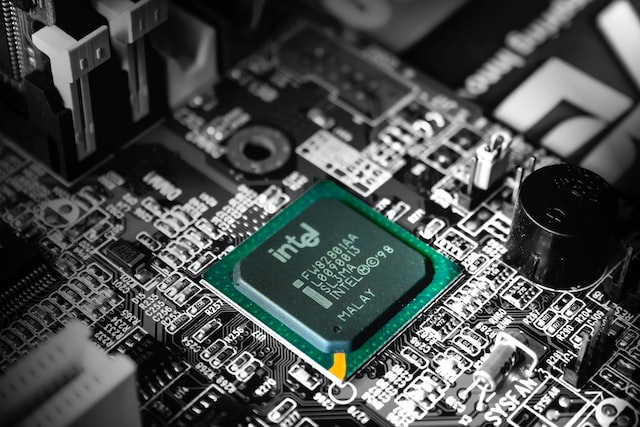

Some of the leading tech companies, including IBM, Nvidia, and Intel, are already building sophisticated AI solutions for the manufacturing industry. This collaboration of tech and manufacturing will be very crucial to achieving the full benefits of AI in this industry. Let’s look at some of the major players impacting AI in manufacturing.

Companies creating AI solutions for manufacturing

- IBM: It is one of the big tech companies playing a massive role in the 4IR thanks to its cloud and AI solutions. Companies are using IBM’s AI solutions, such as predictive intelligence and automation, to compile rich data insights that track business trends, anticipate potential risks and determine how to best incorporate automation technology.

- Nvidia: It has created the Omniverse platform that enables companies in the manufacturing industry to create digital twins of their facilities. Having digital twins makes it much easier, safer, and cheaper to test manufacturing concepts before applying them in the real world.

- Intel: Intel is mainly known for its cutting-edge chip technologies. However, Intel has also developed several AI tools that companies in manufacturing can use to generate real-time data that enables teams to quickly fine-tune workflows. Intel is also heavily investing in technologies aimed at improving Simulation, machine vision and predictive maintenance.

- Rockwell Automation: Their flagship product, FactoryTalk Analytics LogixAI, has AI and machine learning capabilities that help companies to foresee potential setbacks, encourage proactive measures and maintain product quality.

- Uptake: This is another company designing AI solutions tailored for the manufacturing industry. Uptake’s AI solutions use material, process and equipment data to generate recommendations on reducing energy costs, optimizing labor and product reliability and enhancing the overall operations.

Use cases on AI in manufacturing

There are a lot of practical applications of AI in manufacturing. Some of the common ones currently being implemented by several companies in this industry include the following.

Inventory management

For manufacturing companies, inventory includes both the finished products and the raw materials/parts used to create these products. In this section of manufacturing, AI is mainly used to track production floor operations to ensure the required raw materials are availed in time and to prevent overstocking in seasons when they are not needed.

AI is also used in demand forecasting. Predicting the demand for the company’s products makes it easy to optimize operations in order to meet this demand. AI tools used for forecasting use the previous data and the current market conditions to predict the potential demand for the company’s products.

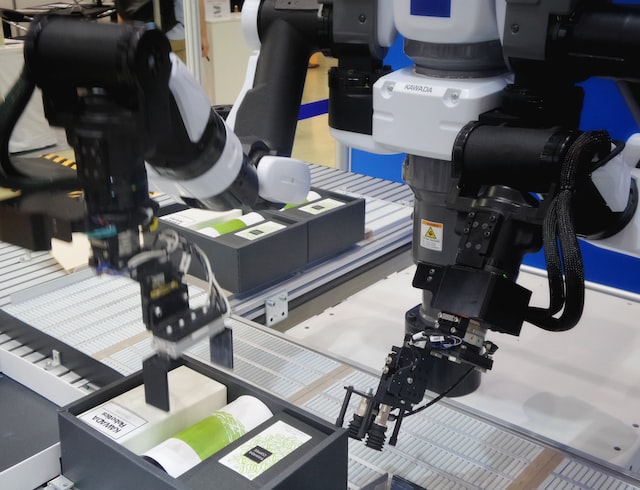

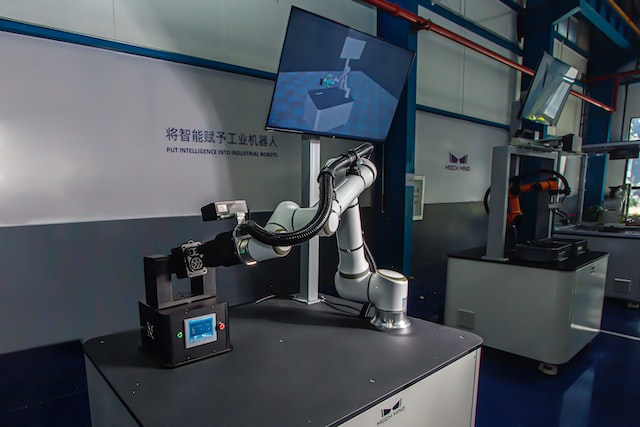

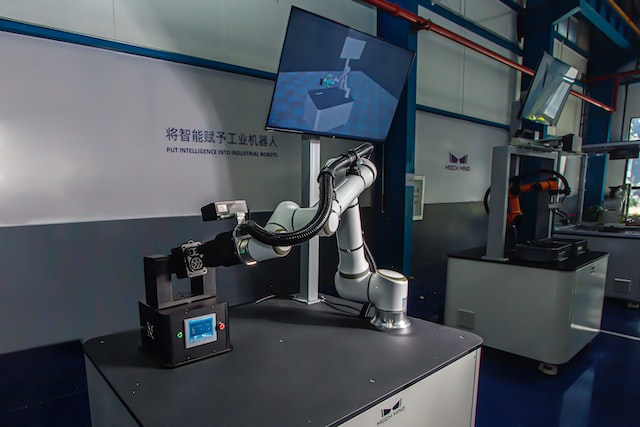

AI-based robots

This is probably one of the popular use cases of AI in this industry. AI-based robots are mainly used to do repetitive tasks in manufacturing operations. Some of these tasks include welding, painting, drilling, product inspection, die casting, and grinding. Using robots for such tasks significantly lowers operational costs and also boosts the production capacity of a manufacturing facility.

AI-based robots are also used for tasks that are too risky to be done by humans. Such tasks include working in foundry factories, heavy lifting, and working in environments filled with dangerous chemicals. Using robots for these kinds of tasks is both a cost and life-saving decision.

AI autonomous vehicles

Autonomous vehicles are already being used on production floors to move things around. Porsche is one of the popular companies using self-driving vehicles to do a number of their production operations. Self-driving vehicles can optimize deliveries, operate 24/7, and speed up the overall delivery process within the manufacturing plant.

The AI systems in these vehicles use data gathered by cameras and lidar scanners to maneuver through the obstacles along the way. They also rely on data provided to them to decide where to go at any given time.

Using AI-powered design software

Most of the modern software tools used to design products have AI capabilities that enable engineers to rapidly create designs for products yet to be manufactured. Nissan, one of the most popular car makers, is already taking advantage of AI-based software to generate never-seen-before car designs within a few seconds. Engineers would need several days to create such designs. Despite not being perfect, AI-generated product designs are a good starting point for creating unique products instead of starting from scratch.

For AI-powered tools, engineers have to provide several parameters, including raw materials, size and weight, manufacturing methods, cost and other resource constraints. The algorithms of the AI-powered software use these parameters to generate various design permutations for a product.

This speeds up the overall design process for products. Most of the modern CAM/CAM software, including Solidworks, Catia, Ansys, and Solid Edge, have slowly been adding AI features in the last couple of years.

Predictive maintenance

Another common use case of AI in manufacturing is in maintenance. AI systems can be used to determine when specific equipment should be maintained to avoid downtime due to random breakdowns. Traditionally, equipment in any manufacturing facility was maintained after a specific period of time or repaired when it breaks down.

With predictive maintenance, AI algorithms are used to determine the appropriate time when the different equipment in a manufacturing plant should be maintained. These algorithms use data such as the equipment’s condition, active hours, efficiency, and other equipment reliability parameters to determine the most appropriate maintenance schedule.

Defects inspection

Before a product is shipped out of manufacturing, it has to be thoroughly inspected to ensure it meets the minimum quality standards. Doing these inspections manually consumes a lot of time and is also prone to human errors. The good news is that we now have AI-powered tools that can do these defect inspections much faster and more accurately.

These tools use advanced cameras and computer vision algorithms to identify any dents, cracks, scratches and overall damage to the product. FIH Mobile, one of the largest smartphone and wireless communication device manufacturers, is already using AI-powered tools to do defect inspections in its manufacturing facilities.

Product assembling

Assembling products is one of the most costly manufacturing operations for companies such as car makers like Ford, Tesla, or GM. Elon, the CEO of Tesla, confessed that building the production system of the car is “100 times” as hard as building the car itself. However, an efficient production system can significantly lower the operating costs in the manufacturing plant.

Product assembling is a major operation in the production system. Automating product assemblies using robotic arms and other AI-powered devices has the potential to boost the efficiency of the overall production system of any manufacturing plant. Tesla has automated over 75% of its production line, one of the reasons behind the rapid growth in its production capacity.

Most of the big players in the automotive industry have also heavily invested in using AI solutions to automate their assembly lines. Automating assembly lines can significantly boost the production capacity of any manufacturing facility.

Reading texts and bar codes.

Bar codes and texts are usually written on the packaging or the actual product in order to ease identification. Manufacturing facilities are now using AI-powered tools to read bar codes and texts much faster. The ability to read codes and texts on products and documents speeds up operations and reduces human error by extracting data from all incoming documents.

AI-powered security systems

Manufacturing facilities face many security threats that can potentially lead to the shutting down of the entire plant if not dealt with in time. Manufacturing facilities now use biometric authentication mechanisms such as fingerprint scanners and facial recognition cameras to determine who accesses the most sensitive spots in the facility.

Sensitive areas such as the data centers shouldn’t be accessed by everyone in the factory, and using biometric authentication makes this process much easier. AI can also be used in the surveillance systems of the manufacturing facility to ensure its safety. These systems are designed to trigger alerts in case of any suspicious events.

Pros and cons of AI in manufacturing

Pros

- It lowers the production costs: Using automation reduces the costs of recruiting and training the workforce to do the jobs that can be done by robots. It should also be noted that robots can be deployed 24/7, equivalent to 3 standard shifts for human labor.

- Boost production capacity: Using automation in product assemblies and other manufacturing operations improves the production capacity of any manufacturing plant.

- Improved productivity of human labor: Humans are more productive when doing fun and non-boring tasks. The tedious tasks are passed over to robots, so human labor focuses on work that involves making critical and dynamic decisions that can’t be made by AI.

- It reduces downtime: Using predictive maintenance can significantly lower the number of breakdowns in the manufacturing facility. Manufacturing facilities usually have unusual breakdowns that can’t be anticipated using the traditional maintenance methods. Such breakdowns can easily be avoided by using AI-powered predictive maintenance systems.

- Improving product quality: Using AI tools for product inspection and quality assurance ensures all products shipped out of the manufacturing facility meet the pre-determined standards. It also eliminated the chances of errors that could occur if these inspections were done by humans.

- Improves safety in manufacturing facilities: Safeguarding the lives of workers should be a top priority for any manufacturing facility. Thanks to automation, most of the risky operations that were initially done by humans can now be done by robots.

Cons

- High initial investment costs: Building an automated production facility is very expensive. The technological complexity of building such facilities is one of the reasons behind the high cost.

- AI-powered tools are vulnerable to cyber threats: A manufacturing facility comprised of interconnected devices can be compromised by hackers if proper cybersecurity measures are not deployed.

- Requires hiring more experts: Despite lowering the costs of hiring equipment operators, using automation will require hiring highly skilled engineers to manage the sophisticated AI systems used to run the manufacturing facility. Getting these talented engineers is at times hard due to their high demand.

Final thoughts

AI has played a very crucial role in revolutionizing several operations in manufacturing. Many companies have invested millions and billions of dollars in integrating AI into their manufacturing operations. The major benefits of using AI in manufacturing include lower operational costs, minimizing downtimes, improving safety, and boosting the production capacity.

However, integrating AI into manufacturing has several risks and threats that companies must be aware of before adopting this technology.